Private projects are different from business projects, aren’t they. In a way yes and no.

The budget is smaller for sure but all other steps are similar in private and in business projects.

In our case the scope was clear: build a bike port for the family bikes.

Limitations were: maximum 2.00 to 2.50 meters, because of the small environment.

Design expectation: it should be optical light weighted, not that kind of massive block house like in the canadian mountains (because of the small place).

Budget: the budget was roughly calculated by orientation on the price matrix of ready-to-bulid-garden-houses like you can buy in DIY-stores.

Time: before autumn begins with its cold, rainy weather. Yes, we had the luxury of missing marketing campaigns or pressure from a superior. But there were clear unspoken expectations of make it happen in 2015 or …!

Quality: must look professional, stand solid.

Team staffing: was a bit difficult, because of the different levels of knowledge of the involved persons. and because of the family affairs. but in the end, we had team of two main workers and from time to time an expert for screws or support by ready-to-eat-meals or coffee-breaks.

All these requirements were discussed at the dining table and refined on a daily base. Documentation were made manual on paper. BUT – to get an impression if the idea of an light weighted bike ports meets reality, a 3-D-Modell was created. Yes, really. This step was not planned, it happened, because of the 3-D-designer-skills of a good friend of the family, who was deeply involved in the creation phase and later in the building process.

Intermediate resume: you better have a 3-D-best-friend for planning such small but fine architecture projects.

What is with specialists for special jobs? We engaged a gardener for the preparation of the underground – excavation work, sand, stones, cement, ground and tiler works.

Did we had a clear leadership over the complete project? No. Leadership changed in this project from phase to phase. During the conception phase it was my wife. During the budget phase, it was myself. During the construction phase it was my 3-D-construction-friend. In between the project team had changing consultants, f.e. supporting the team with helpful tools (circular saw & Schraubzwingen) and advice about choosing the right screws. The team made the decision about leadership without discussion, it worked unspoken, because every team member had an idea about the different skills in the team and therefore changing leaders for changing jobs were the best way for having the right woman/ man in place for the jobs she/ he knows best.

Was the project method 100% agile or did we had classic project management elements? Yes, indeed, we also used classic elements. We used budget planning, we used a timetable for buying our building material, we made a concept in the beginning, refined this concept, we made this 3-D-modell, made a list of the building material, we agreed on milestones (finishing of the scaffold, ready with planking, assembly the roof & gutter).

On the other hand we had no complete detailed project plan, and we changed some things during the building phase, we also had to find solutions for questions coming up while building the bike port, we had to overwork our estimation of how long we need for the first milestones. At the end it was a mixture between agile (65%) and waterfall (35%) – even hybrid project management.

Which really works 😉

Need a confirmation?

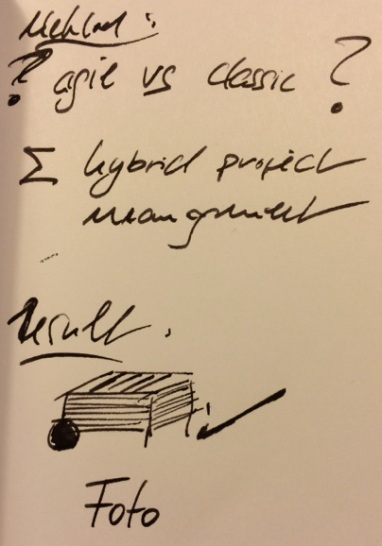

Take a look at the result: